Preloader Close

OUr Infrastructure

WELDRO

WELDRO® is a programmable, computer-controlled, Automatic CO2/MAG/MIG arc welding machine, which is developed by Applied Engineering and Technology (P) Ltd through Its R&D facility.

WELDRO® is made for high precision welding process, which is used in components like ABS braking systems in Automobile vehicles.

The braking system components cannot afford to get failed during the operation.

WELDRO® produces, consistent quality weld joints and there will be no field failure But the manual welding process is prone to defects due to inconsistent welding processes.

A few important features of the WELDRO®

- Simple, Safe & speedy.

- Quality Assured through Online in-process monitoring.

- Quality Assured through Controlled atmosphere welding.

- Quality Assured through Accuracy of ‡ 0.2 mm. for runout.

- Quality Assured through Actual Value Recording (AVR) System.

- Environment Friendly

- Flexible - Customizable to a variety of products.

- Optimized - Consumes less power and consumables.

- Space Saver - Compact design and occupies very little floor space.

- Low cost and good Return on Investment.

OUr Infrastructure

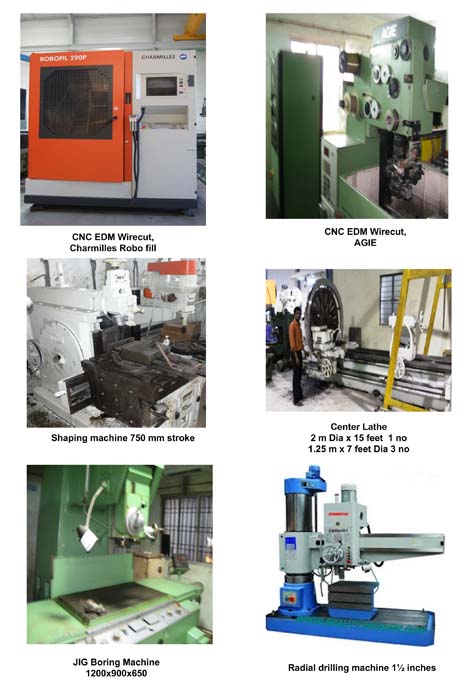

Tool Room & Special Machine Building Facility

- CNC EDM Wire cut, Charmille Robofil

- AGIE Cut EDM CNC Wire Cut

- JIG Boring Machine 1200 x 900 x 650(Praaga)

- Horizontal Boring machine 1 no

- Center Dia 1900 mm Lathe 15 feet, 1 no

- Center Dia 800 Lathe 7 feet, 3 no

- Shaping m/c 750 mm stroke, 1 no

- Radial Drilling m/c 11/2 inch 1 no

- Vertical milling and boring m/c with DRO (M1TR), 1no

- Surface grinding ( table size 450mmx300mm ),1 no

- Cylindrical Grinding Machine

- Hydraulic feed Surface grinding (1200mmx500mm ),2 no

- Fitting tools

- Surface table

- Height master

- Measuring instruments

- 10 ton hand press for fitting and bearing assembly

- A frame with 2 T crane

- 3000mm x 2000mm Height gauge 1 no

OUr Infrastructure

Tool Room & Machine Shop Facility

- Center Lathe 41/2 feet 2 nos

- Gang Drilling machine

- Vertical Milling Machine 2 nos

- Horizontal milling machine 1 no

- VTL dia 2000 mm 1 no

- CNC Lathe ACE Jobber excel

- Radial drilling 25 mm dia Radial drilling 36 mm dia

- Bench drilling Machine 6 nos

- Cutter Blade grinding machine 4 nos

- Band Saw cutting machine

OUr Infrastructure

Fabrication Facility

- TIG welding

- MIG Welding

- CNC Plasma cutting machine

- Air Compressor and painting gun

- Hand & Bench grinder

- Radial drilling

- 2 m dia centre lathe, Horizontal boring

- Shearing machine

- WELDRO® Automated welding m/c

- Folding machine

- SPOT & Projection welding m/c

- Mobile and Gantry crane with 12 Ton Hoist

- Shot blasting and painting

OUr Infrastructure

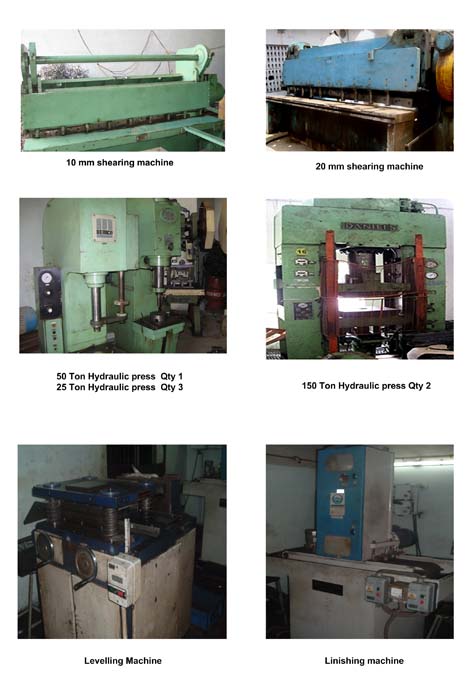

Press Shop Facility

- 250 T Mechanical press C frame

- 250 T Mechanical press H frame 3 nos

- 150 T Mechanical press

- 75 T Mechanical press

- 60 ton mechanical press, 2 nos

- 30 ton mechanical press, 13 nos

- 20 ton mechanical press, 2 nos

- 50 T Hydraulic press 1 nos

- 25 T Hydraulic press 3 nos

- 100T Hydraulic press 4 nos

- 250T Hydraulic press 2 nos

- 500T Hydraulic press H Frame Power Shearing machine 2 nos

- 100 Ton High speed press 2 nos

- Servo feeder and Coil stand 2 nos

- Linishing machine, 3 nos

- Levelling machine

- Grind Master (Belt grinding m/c)

- Vibro Barrel

- Rotary barrel

- Weighing m/c

OUr Infrastructure

Design Centre

- Design workstations

- Product simulation facility

- Process simulation facility

- Prototype and validation facility

OUr Infrastructure

R&D Facility

- Control Systems Lab

- Metal forming Lab

- Heat treatment Lab

- Software Development Lab

OUr Infrastructure

Quality

- ISO/TS 16949:2009 Certification

- Standard Room

- CMM

- Profile Projector

- Hardness Tester

- UTM

- Surface table

- Oscilloscope, Tachometer, multimeter

- Micrometre, Vernier, Dial gauge, Slip Gauges etc.